Beef Dryer

Continuous and automatic operation.

Large output capacity.

Short drying time.

Flexibility in selecting heat sources.

Heat source can be freely chosen according to the local situation. Wood, coal, biomass granules, steam, natural gas, diesel, air chamber (electricity), etc.

Product Description

Drying fresh beef into beef jerky can not only preserve it for a longer time; And it's more chewy. Beef jerky contains a variety of minerals and amino acids required by the human body, which not only maintains the chewy flavor of beef but also keeps it from spoiling for a long time.

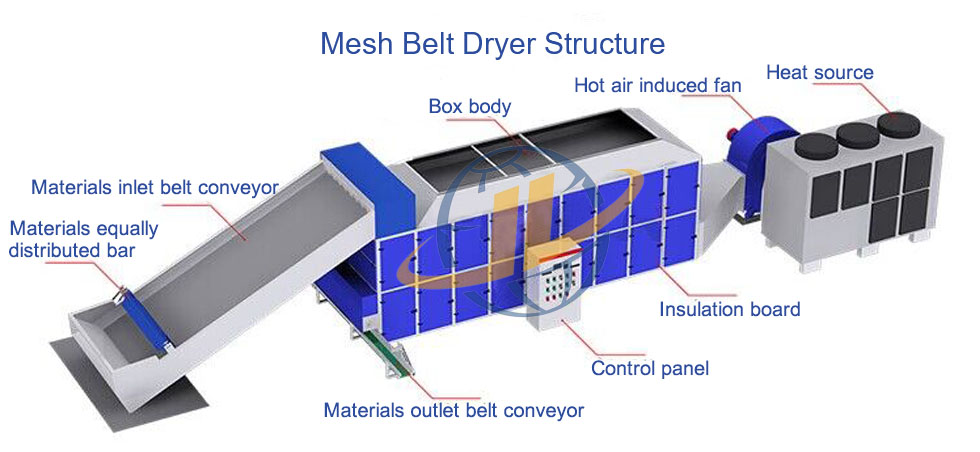

Ⅰ.Construction Of Beef Dryer:

The mesh belt dryer consists of a feeder conveyor, an equally distributed bar for material distribution, a main drying body with 5-7 layers of stainless steel mesh belts, optional heat source, a centrifugal fan for hot air circulation, humidity exhaust fans, an output conveyor belt, gear-drive equipment, and panel control. The width of the mesh belt dryer is 2-3 meters,while the length and number of layers can be customized according to the client's capacity. Usually, it is recommended to have a length of at least 7 meters for cost-effectiveness.

Ⅱ.Working Principle Of Beef Dryer:

The beef is transported to the top layer of the drying body through a belt conveyor and then falls onto the mesh belt. With the continuous movement of the mesh belt, the beef undergoes dynamic drying as it moves from the top layer to the bottom without any interruptions.During this process, the beef is automatically reversed each time it falls onto the lower layer, which accelerates the drying process. Compared to other drying machines, the mesh belt dryer requires less time to dry the same materials.Following heat source is optional according to your local fuel.

The mesh belt dryer is a highly advanced drying machine that utilizes continuous hot air circulation for efficient drying. It ensures minimal heat waste and is widely employed in the drying of large quantities of materials.

Ⅲ.How to dry beef :

1: Position the beef on the conveyor belt of the beef dryer, ensuring that it is evenly spread out. The homogenizing device on the conveyor belt helps to achieve this. Maintain a stacking thickness of 10-20cm for the beef.

2: Once inside the beef dryer, the beef follows a serpentine path in an "S" shape. The transmission system of the beef dryer is equipped with a variable-frequency speed-regulating motor, allowing for precise control of the drying time based on the moisture content variation of the beef.

3: The hot air blower generates sufficient wind speed and pressure to ensure the even distribution of hot air throughout the beef dryer. Due to the higher pressure at the bottom compared to the top, the hot air naturally rises and passes through each layer of the mesh belt. As the beef moves and rolls, it comes into full contact with the hot air, facilitating efficient heat exchange and improving the drying efficiency. Eventually, the dried beef is discharged through the last layer.

Ⅳ.Advantages of the Beef Dryer:

- 01High Capacity:The beef dryer has continuous automatic production, fast dehydration speed. short drying time and high output.

- 02High Quality: Beef can be maintained full of shape, bright, color.

- 03Clean and Sanitation: The entire beef drying process is completed in a closed box, free from external pollution.

- 04Intelligent and Controllable: High degree of automation equipment, simple operation,Drying area, air pressure, air flow, drying temperature, and belt running speed can be adjust.

- 05Wide Usage: Can be used for material from any field.

- 06Flexible Heat Source Selection: Coal,wood chips,natural gas,diesel,propane,electricity etc.

Technical Parameters

| Model | JL-1*10m | JL-1*12m | JL-1*17m |

| Layer | 3layers,4 layers,5 layers,6 layers,7 layers | ||

| Material thickness | 50-200mm | ||

| Drying temperature | 40-120℃ | ||

| Drying time | 0.5-5hours | ||

| Moisture reduce | 75%-80%(customized) | ||

| Main equipment motor | 2.2kw | 2.2kw | 2.2kw |

| Hot air draft fan | 10C-15.5KW | 10C-18.5KW | 12C-30KW |

| Materials discharge conveyor | 0.12KW(Gear speed regulating motor) | ||

| The above parameters are for reference,we can provide suitable solution according to customer's requirements. | |||

Contact us

We would like to hear from you, please contact us if you have any questions. We will reply you within 24 hours.