Forage Dryer

Quick cycle, high output, and environmentally friendly drying process.

Uniform and efficient heat and mass exchange.

Energy-saving with automatic circulation of pure hot air.

Versatile machine that saves both cost and space.

Heat source can be freely chosen according to the local situation. Wood, coal, biomass granules, steam, natural gas, diesel, air chamber (electricity), etc.

Product Description

After drying, fresh grass turns into hay, which is easy to preserve and transport for a long time, does not rot or spoil, and can also be used as a culture medium for flower fertilizer and fungi with other raw materials. Most of them are used for animal husbandry and supply.

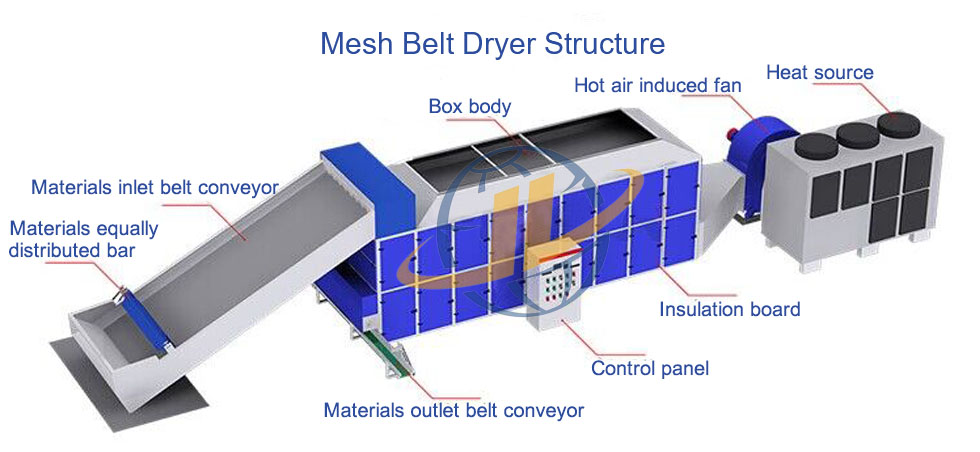

Ⅰ.Construction Of Forage Dryer:

The mesh belt dryer consists of a feeder conveyor, an equally distributed bar for material distribution, a main drying body with 5-7 layers of stainless steel mesh belts, optional heat source, a centrifugal fan for hot air circulation, humidity exhaust fans, an output conveyor belt, gear-drive equipment, and panel control. The width of the mesh belt dryer is 2-3 meters,while the length and number of layers can be customized according to the client's capacity. Usually, it is recommended to have a length of at least 7 meters for cost-effectiveness.

Ⅱ.Working Principle Of Forage Dryer:

The forage is transported to the top layer of the drying body through a belt conveyor and then falls onto the mesh belt. With the continuous movement of the mesh belt,the forage undergoes dynamic drying as it moves from the top layer to the bottom without any interruptions.During this process, the forage is automatically reversed each time it falls onto the lower layer, which accelerates the drying process. Compared to other drying machines, the mesh belt dryer requires less time to dry the same materials.Following heat source is optional according to your local fuel.

The forage is put into the dryer from the upper layer, and an automatic spreading device controls the thickness of the forage spread. The mesh belt drives the forage to move from the upper layer to the lower layer. Throughout this process, the forage undergoes multiple falls, ensuring thorough turning and even drying. The dried forage is discharged from the bottom layer, where it comes into full contact with high-temperature hot air to achieve the desired drying effect.

Ⅲ.Application of Forage Dryer:

The multi-layer continuous dryer offers rapid dewatering and drying capabilities, while being user-friendly and efficient. It is designed to meet the requirements of large-scale continuous production. The mesh belt drying equipment finds widespread applications in various industries, including food processing (such as noodles and pasta), dried fruits (like dates, apricots, cashews, and pistachios), floral teas (such as rose, honeysuckle, and lily of the valley), agricultural by-products (like corn and damp honeysuckle), dehydrated vegetables (including garlic, ginger, onion, cabbage, and spinach), fruits (such as apples, potato chips, raisins, and melons), Chinese herbs (such as forsythia, yellow marshmallow, and goji berries), aquatic products, local specialties, feed, and chemical raw materials. It is suitable for dehydrating and drying flakes, strips, blocks, and granular materials.

Ⅳ.Advantages of Forage Dryer:

- 01Uniform drying effect: The chili keep moving on the belt, during this process, both side of the material can fully contact the hot air, so that the drying effect can be uniform.

- 02Adjustable speed: Drying temperature,moisture can be ajusted by the control panel by adjust the mesh belt running speed and air rate.

- 03Various fuel: Dryer machine can use coal, wood, gas, diesel, electricity, can meet different customer requirements.

Technical Parameters

| Model | JL-1*10m | JL-1*12m | JL-1*17m |

| Layer | 3 layer,4 layers,5 layers,6 layers,7 layers | ||

| Material thickness | 50-200mm | ||

| Drying temperature | 40-120℃ | ||

| Drying time | 0.5-5hours | ||

| Moisture reduce | 75%-80%(customized) | ||

| Main equipment motor | 2.2kw | 2.2kw | 2.2kw |

| Hot air draft fan | 10C-15.5KW | 10C-18.5KW | 12C-30KW |

| Dischage conveyor | 0.12KW(Gear speed regulating motor) | ||

| The above parameters are for reference,we can provide suitable solution according to customer's requirements. | |||

Contact us

We would like to hear from you, please contact us if you have any questions. We will reply you within 24 hours.