Papaya Drying Room

Excellent Preservation

Versatile Application

Advanced Drying Equipment

Heat source can be freely chosen according to the local situation. Wood, coal, biomass granules, steam, natural gas, diesel, air chamber (electricity), etc.

Product Description

The papaya drying room is specifically designed to address the challenges of drying papaya effectively. Traditional drying methods may not be sufficient due to the high sugar content of papaya. To overcome this, our air heat pump papaya dryer offers a superior drying solution.Unlike traditional approaches that rely on coal-fired boilers or hot blast stoves, our papaya dryer utilizes an air heat pump system.With automated controls, the drying process can be carried out without the need for constant manual supervision.Our papaya drying room offers a reliable and efficient solution for papaya producers, ensuring optimal drying conditions and preserving the flavor, texture, and nutritional value of the papaya fruit.

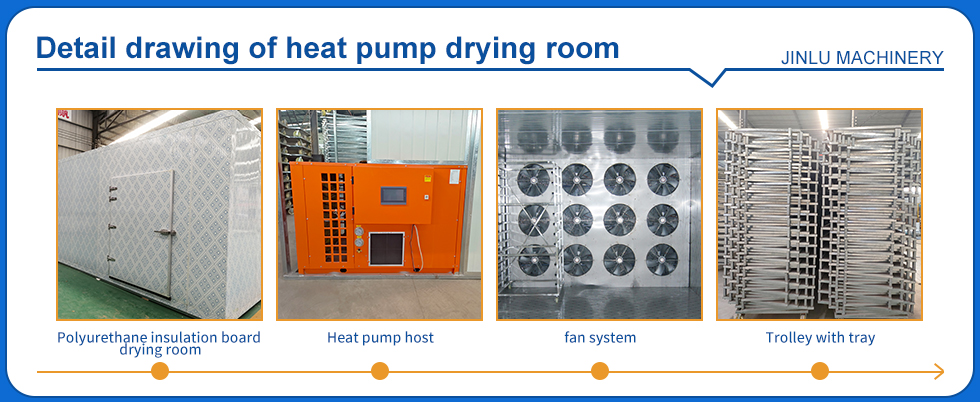

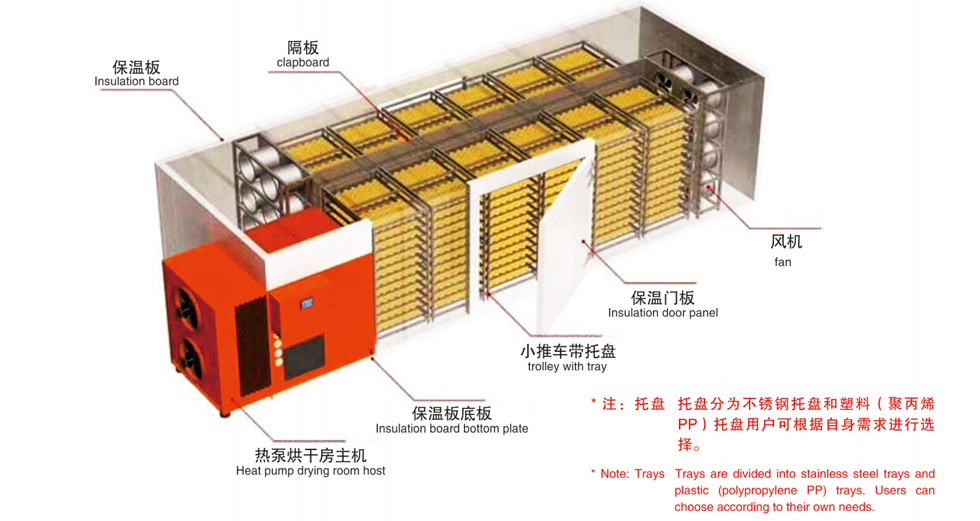

Ⅰ.Construction Of Oyster Mushroom Drying Room:

Drying machine is made of heating system (including but not limited to coal/firewood, wooden pellets, gas, biogas, steam, liquid fuel, electricity etc )drying room, certain number movable carts inside to load drying materials. There are usually 2/4/6/8/10/12/18/24 movable carts inside based on different capacity.

Ⅱ.Air Source Heat Pump Drying Principle:

The papaya drying room is specifically designed to address the challenges of drying papaya effectively. Traditional drying methods may not be sufficient due to the high sugar content of papaya. To overcome this, our air heat pump papaya dryer offers a superior drying solution.Unlike traditional approaches that rely on coal-fired boilers or hot blast stoves, our papaya dryer utilizes an air heat pump system.With automated controls, the drying process can be carried out without the need for constant manual supervision.Our papaya drying room offers a reliable and efficient solution for papaya producers, ensuring optimal drying conditions and preserving the flavor, texture, and nutritional value of the papaya fruit.

Ⅲ.Advantages Of Papaya Drying Room:

- 01 Excellent Preservation: Optimal temperature and humidity control for preserving flavor, color, and nutrition, ensuring high-quality dried papaya with extended shelf life.

- 02Versatile Application: Accommodates various papaya varieties and sizes, allowing customization of texture and moisture content for specific requirements.

- 03 Advanced Drying Equipment: Utilizes advanced heat exchange, airflow control, and moisture removal mechanisms for uniform and efficient drying, ensuring consistent results.

- 04 Energy-efficient Operation: Incorporates energy-saving features like heat pump systems and insulation materials, reducing energy consumption and operational costs.

- 05 User-friendly Controls: Easy-to-use controls enable precise adjustment of drying parameters, ensuring optimal conditions. Intuitive interface and automation enhance productivity and usability.

Technical Parameters

| Model | Length*width*height(mm) | Heat pump power (P) (Copeland compressor) |

Number of small carts (vehicles) |

Number of pallets (pcs) |

Number of fans (units) |

Pallet size 10 layers(mm) |

Approximate drying yield/batch (kg) |

| 4-car side air supply |

4500*2300*2100 |

3 | 4 | 40 | 2 | 1400*900 | 1200 |

| 4 car rear air supply | 6000*1800*2500 | 7 | 4 | 40 | 4 | 1400*900 | 1200 |

| 6 car rear air supply | 6500*2300*2500 | 7 | 6 | 60 | 6 | 1400*900 | 1800 |

| 8 car rear air supply | 8000*2300*2500 | 7 | 8 | 80 | 6 | 1400*900 | 2400 |

| 10 car rear air supply | 7000*3300*2500 | 15 | 10 | 100 | 8 | 1400*900 | 3000 |

| 12 car rear air supply | 8000*3300*2500 | 15 | 12 | 120 | 8 | 1400*900 | 3600 |

| 18 car rear air supply | 8000*4800*2600 | 2*15 | 18 | 180 | 10 | 1400*900 | 5400 |

| 24 car rear air supply | 8000*6200*2600 | 2*15 | 24 | 240 | 12 | 1400*900 | 7200 |

| The above parameters are for reference only and capacity is specific to the sharpped papaya to be dried. | |||||||

Contact us

We would like to hear from you, please contact us if you have any questions. We will reply you within 24 hours.