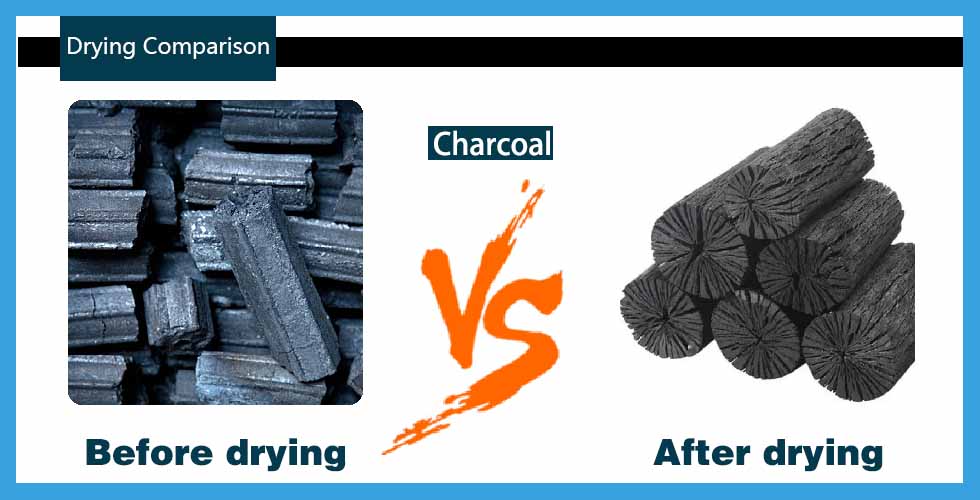

Charcoal Dryer

Intelligent Control

High Efficiency

Energy Saving

Environmentally Friendly & Pollution-free

Safe and Reliable Operation

Heat source can be freely chosen according to the local situation. Wood, coal, biomass granules, steam, natural gas, diesel, air chamber (electricity), etc.

Product Description

The charcoal dryer is a versatile drying equipment that offers efficient drying solutions for a wide range of products. Its applications extend beyond charcoal to include agricultural products, medicinal herbs, scented tea, food, seafood, spices, wood furniture, tobacco, industrial products, and more. With its adaptability and effectiveness, the charcoal dryer is a valuable asset in various industries and ensures optimal drying results for different types of materials.

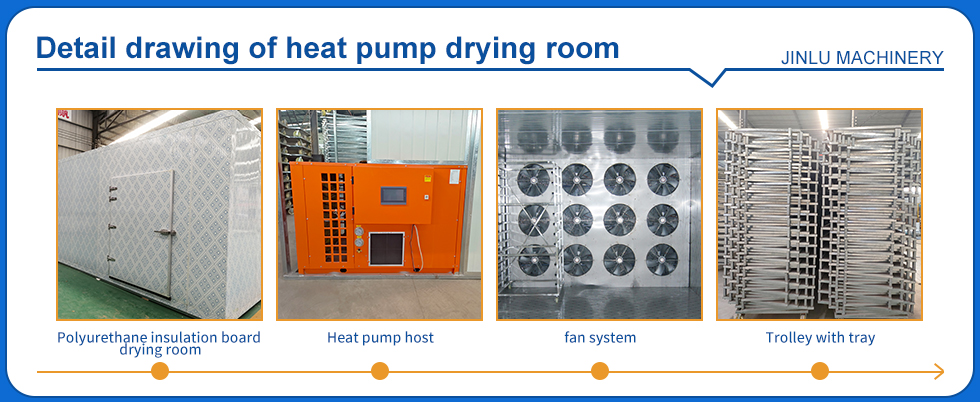

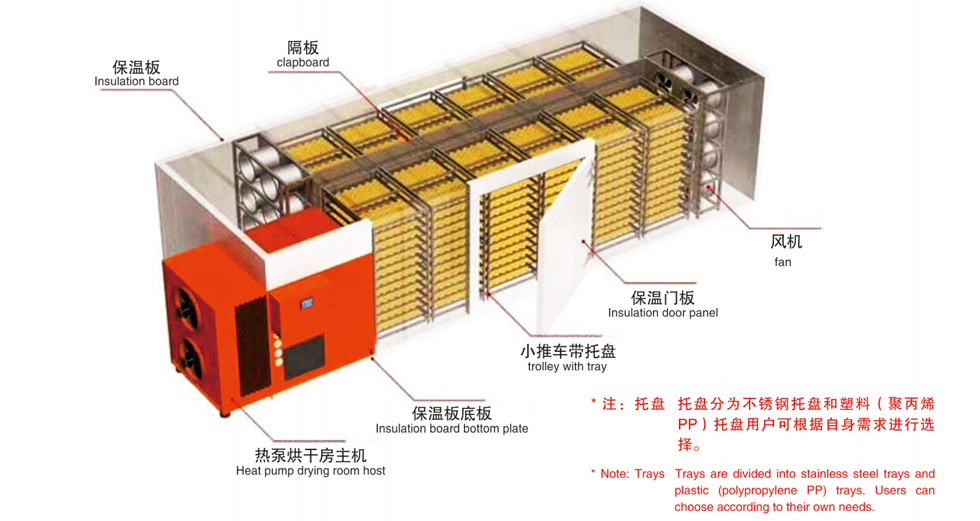

Ⅰ.Construction Of The Charcoal Drying Room:

Drying machine is made of heating system (including but not limited to coal/firewood, wooden pellets, gas, biogas, steam, liquid fuel, electricity etc ),drying room, certain number movable carts inside to load drying materials.There are usually 2/4/6/8/10/12/18/24 movable carts inside based on different capacity.

Ⅱ.Working Principle Of Charcoal Dryer:

The working principle of a charcoal dryer is based on the reverse Carnot cycle. It uses a small amount of electrical energy and a compressor to evaporate the working fluid into a gaseous state in the evaporator after passing through the expansion valve. During this process, it absorbs a large amount of heat energy from the air. The gaseous working fluid is then compressed by the compressor into a high-temperature, high-pressure gas, which enters the condenser to release heat and heat the drying medium. This cycle of heating is continuously repeated.

A charcoal dryer consists of a charcoal drying and dehumidification unit (with adjustable temperature range of 20℃ to 75℃ and adjustable humidity range of 5% to 95%), an insulated box, a hot air circulation system, and intelligent control components. The heat generated by the charcoal dryer provides the necessary heat, while the hot air circulation system ensures uniform temperature and airflow throughout the drying chamber. The intelligent control system maintains precise temperature and humidity conditions throughout the drying process, ensuring high-quality drying results.

Ⅲ.Advantages Of A Charcoal Dryer:

- 01Intelligent Control: The charcoal racks filled with charcoal are pushed into the drying chamber, and the desired time, temperature, and humidity control requirements are set. The charcoal dryer is then activated. It operates automatically without the need for manual supervision, and the drying process stops automatically when completed.

- 02High Efficiency & Energy Saving: The charcoal dryer consumes only a small amount of electrical energy while absorbing a significant amount of heat from the air. With dual-effect dehumidification technology, it greatly improves the dehumidification performance ratio, resulting in noticeable energy savings.

- 03 Environmentally Friendly & Pollution-Free:The charcoal dryer does not involve any combustion or emissions, making it an environmentally sustainable product.

- 04 Safe & Reliable Operation: The entire system operates in a semi-enclosed state during drying, ensuring safe and reliable operation.

Technical Parameters

| Model | Length*width*height(mm) | Heat pump power (P) (Copeland compressor) |

Number of small carts (vehicles) |

Number of pallets (pcs) |

Number of fans (units) |

Pallet size 10 layers(mm) |

Approximate drying yield/ batch (kg) |

| 4 car side air supply | 4500*2300*2100 | 3 | 4 | 40 | 2 | 1400*900 | 1000 |

| 4 car rear air supply | 6000*1800*2500 | 7 | 4 | 40 | 4 | 1400*900 | 1000 |

| 6 car rear air supply | 6500*2300*2500 | 7 | 6 | 60 | 6 | 1400*900 | 1500 |

| 8 car rear air supply | 8000*2300*2500 | 7 | 8 | 80 | 6 | 1400*900 | 2000 |

| 10 car rear air supply | 7000*3300*2500 | 15 | 10 | 100 | 8 | 1400*900 | 2500 |

| 12 car rear air supply | 8000*3300*2500 | 15 | 12 | 120 | 8 | 1400*900 | 3000 |

| 18 car rear air supply | 8000*4800*2600 | 2*15 | 18 | 180 | 10 | 1400*900 | 4500 |

| 24 car rear air supply | 8000*6200*2600 | 2*15 | 24 | 240 | 12 | 1400*900 | 6000 |

| Charcoal production depends on the actual situation | |||||||

Contact us

We would like to hear from you, please contact us if you have any questions. We will reply you within 24 hours.