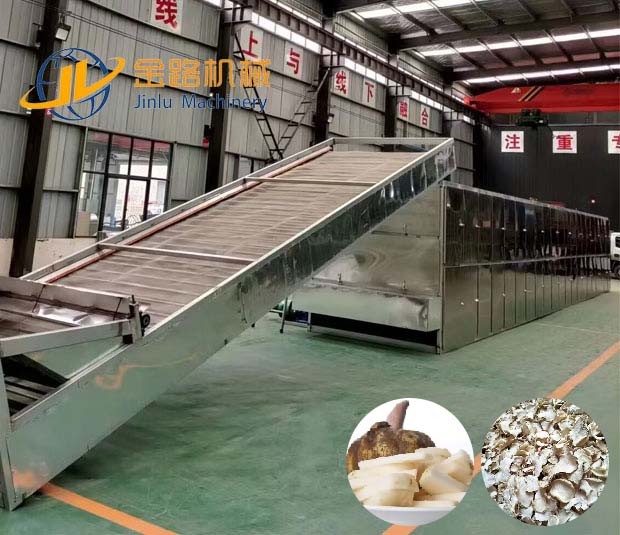

Konjac Dryer

Versatile and widely used for drying grain materials,fruit,herb, vegetables etc.

24-hour continuous working avoiding heat waste

Fully auto and labor saving, 1-2 workers can operate

Large capacity

Heat source can be freely chosen according to the local situation. Wood, coal, biomass granules, steam, natural gas, diesel, air chamber (electricity), etc.

Product Description

Konjac is a beneficial alkaline food. For those who consume too much acidic food, consuming konjac in combination can achieve a balance between food acidity and alkalinity, which is beneficial to human health. Konjac has the characteristics of high moisture content, complex composition, and easy color change. Customers need automated konjac drying equipment to make the dried konjac slices white and of high quality.

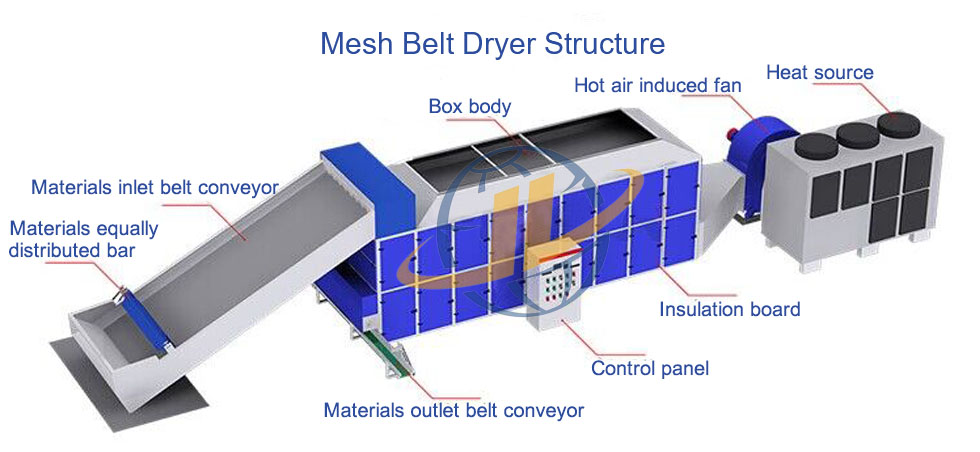

Ⅰ.Construction of Konjac Dryer:

Multi-layer belt dryer mainly consists of a slow-moving stainless steel mesh belt (usually 5 layers, adjustable based on client’s needs ), frame, insulated board shell and a heat source.Partitions are set between the layers to organize the directional flow of the drying medium and make the material dry evenly. The multi-layer belt dryer occupies less land and has a simple structure. Coal, wooden pellets, gas, electricity etc is optional as heating source.

Ⅱ.The principle of Konjac Dryer:

The processing process of konjac is as follows: fresh konjac - cleaning - slicing - lifting input - drying - unloading - packaging.After cleaning and slicing, Konjak are transported by conveyor belt to the top layer of the mesh belt. The host is composed of 3-7 layers of stainless steel mesh belts, driven by chains on both sides, and equipped with baffles on both sides of the mesh belt to prevent materials from falling into the middle of the track. Hot air is provided by energy-saving hot air furnaces that burn coal (or wood, electricity, gas, etc.). The hot air is sent by a blower to the bottom of the dryer, where it first exchanges heat with the drying material through the bottom mesh belt, taking away some moisture, and then passes through layer by layer. The mesh belt forms a countercurrent heat exchange with the material. After the wet air reaches the upper layer and undergoes heat exchange with the wet material, it is basically saturated, enters the dehumidification outlet, and is discharged outdoors by humidity emitting fans.Following heat source is optional according to your local fuel.

Ⅲ.Advantages of Konjac Dryer:

- 01Konjac dryer is widely used for dehydration and drying of various regional and seasonal vegetables and fruits. Such as pepper, camellia oleifera seed, konjac, white radish, yam, bamboo shoots, etc.

- 02The equipment is easy to operate and easy to maintain. The average worker can operate it in one day after learning it.

- 03It has the advantages of small footprint, compact structure, high thermal efficiency, and is not affected by rainy weather.

Technical Parameters

|

Model |

JL-2*7 |

JL-2*10 |

JL-2*20 |

|

Layer numbers |

Five layers, six layers, seven layer optional |

||

|

Shell thickness |

50mm |

||

|

Belt width |

2m |

||

|

Drying area (m2) |

70 |

100 |

200 |

|

Loading capacity (kg/m2) |

10-40 |

||

|

Running speed (m/min) |

0.4-4 adjustable |

||

|

The above parameters are for reference,we can provide suitable solution according to customer's requirements. |

|||

Contact us

We would like to hear from you, please contact us if you have any questions. We will reply you within 24 hours.