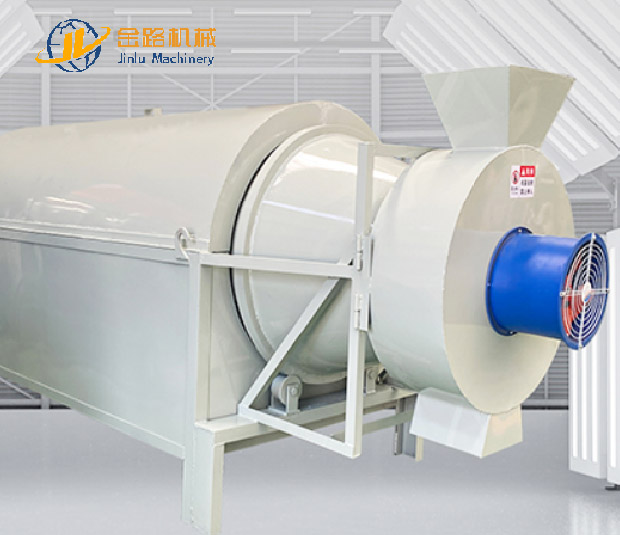

Seaweed Dryer

The seaweed dryer enables:

Capable of producing large quantities of dried seaweed continuously

Ensures excellent drying results

Minimizes labor requirements

Heat source can be freely chosen according to the local situation. Wood, coal, biomass granules, steam, natural gas, diesel, air chamber (electricity), etc.

Product Description

The biomass pellet feed dryer consists of seven major systems, including the heating system (host), drying room system, circulation fan system, drainage system, control system, moisture discharge system, and early warning system. It utilizes a mature and stable air conditioning technology process, ensuring safety and reliability. The seaweed dryer operates on the principle of inverse Carnot, where the working mass absorbs heat from the external environment through a thermal cycle process of compression, condensation, throttling, and re-evaporation. This transfers the heat from the external low temperature environment to the seaweed drying room.

The advantages of biomass pellet fuel in feed dryer are as follows:

- 01Volume compression: Biomass pellets are compact and offer significant volume compression, saving storage space and facilitating transportation while reducing costs.

- 02High combustion efficiency: Biomass pellets have high combustion efficiency, easy burnout, and produce less carbon residue. They have higher volatile matter, lower ignition point, higher density, higher energy density, and longer combustion duration compared to coal.

- 03Cost-effectiveness: The low cost of biomass pellet fuel reduces production expenses and creates higher economic benefits for users.

- 04Versatile energy sources: In addition to biomass pellet fuel, feed dryers can also use gas, oil, electricity, steam, and other energy sources. Users can choose the appropriate energy source based on their production needs.

- 05Environmentally friendly: Biomass pellets do not produce harmful substances like sulfur and phosphorus when burned. After simple tail gas treatment, they can be directly discharged into the atmosphere. The ash produced after burning can be used as potash fertilizer.

- 06Wide range of applications: The feed dryer can be used for drying various residues, such as dry residue, wine lees, soybean residue, starch residue, tofu residue, fermented bacteria residue, fruit residue, tea residue, soy sauce residue, vinegar residue, kitchen waste, etc.

Technical Parameters

| Model | Inputpower | Bodyweight | Equipment power | Thermal power | Matching power |

| RSL45 | 380V | 500KG | 0.55KW | 45million calories | 8-36million calories |

| RSL90 | 380V | 650KG | 1.5KW | 90million calories | 36-75million calories |

| RSL120 | 380V | 750KG | 3KW | 120million calories | 75-110million calories |

Contact us

We would like to hear from you, please contact us if you have any questions. We will reply you within 24 hours.